Welcome to visit our factory !

Welcome to visit our factory !

Email:

hnty@ayxingsheng.comCaSi Wire | CaFe Wire | Carbon Wire | FeTi Wire | ReSiMg Wire | Pure Ca Wire | FeS Wire

Provide FeSi 72% | FeSi 75% | FeSi 70% | FeSi Powder | Factory & Manufacturer

Silicon Metal 553 / 441 / 421 / 3303 / 2202 / 1101, Customized According to Your Needs

HC silicon 6818/6515, various grade for choice, Materials for Steelmaking

SiMn-6517 /6014, silicon manganese is used as a deoxidizer and an alloying element in stee.

Ferro manganese is an ferro alloy whose main components are ferro and manganese. It is used as a deoxidizer, desulfurizer and alloying agent in iron and steel work.

Silicon Slag is a by-product of silicon metal production. It's the separated part which are less purity of silicon metal.

Micro Carbon | Low Carbon | Medium Carbon | High Carbon | Various Grade for Choice. Ferro Chrome is an ferro alloy of chromium and iron, containing 50% to 70% chromium.

Silicon carbide contains two common basic varieties: black silicon carbide and green silicon carbide

Recarburizer, also know as carbon additive, carbon raiser. It is a product for increasing the carbon element (C).

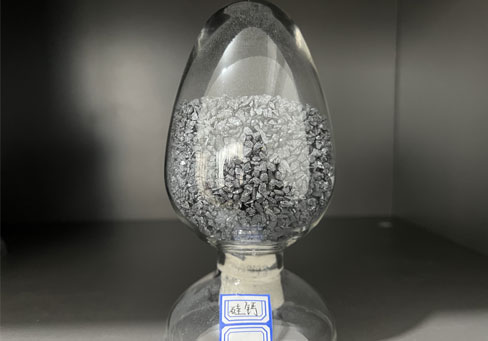

● Ca30 Si60 | Ca30 Si58 | CaSi Powder - Ca28-30% Si50-60%

● Size: 10-80mm 3-8mm 0-3mm 0-200mesh or customized

CaSi alloy is the compound alloy which is composed by silicon, calcium and ferrum. It’s an ideal compound deoxidizer and desulfurizer which can be widely used in the production of steels such as high-quality steel, low-carbon steel, stainless steel and special alloys such as nickel base alloy, titanium base alloy. CaSi alloy can also be applied as the heat-raiser for converter steelmaking, the inoculant for cast iron production and addictive for nodular cast iron production.

|

Grade |

Ca |

Si |

Al |

C |

P |

S |

|

|

≥ |

≤ |

||||

|

Ca28Si50 |

28 |

50 |

2.4 |

1.0 |

0.04 |

0.05 |

|

Ca30Si50 |

30 |

50 |

2.4 |

1.0 |

0.04 |

0.05 |

|

Ca28Si55 |

28 |

55 |

2.4 |

1.0 |

0.04 |

0.05 |

|

Ca30Si55 |

30 |

55 |

2.4 |

1.0 |

0.04 |

0.05 |

|

Ca28Si60 |

28 |

60 |

2.4 |

1.0 |

0.04 |

0.05 |

|

Ca30Si60 |

30 |

60 |

2.4 |

1.0 |

0.04 |

0.05 |

|

Other specifications can be customized.Size 10-80mm 0-3mm or customized. |

||||||

■ Stable reaction and easy operation

■ Uniform chemical composition and low impurities with high performance

■ Products can meet the needs of most customers with varied specifications.

Please feel free to submit your inquiry information to us, We will reply to you as soon as possible.