Welcome to visit our factory !

Welcome to visit our factory !

Email:

hnty@ayxingsheng.comCaSi Wire | CaFe Wire | Carbon Wire | FeTi Wire | ReSiMg Wire | Pure Ca Wire | FeS Wire

Ca30 Si60 | Ca30 Si58 | CaSi Powder - Ca28-30% Si50-60% | Third Party Inspection

●CaSi Wire | Ca Wire | FeTi Wire | CaFe Wire | C Cored Wire | CaAl Wire | ReSiMg Wire | FeS Wire

●20 years of experience in cored wire production | Factory direct sales at competitive prices

Calcium Silicon Cored Wire (CaSi Wire) is a commonly used metallurgical material, primarily for deoxidation and desulfurization in steelmaking. It consists of silicon-calcium alloy powder encased in a steel strip, which allows for precise control over the addition of alloying elements during the steelmaking process, ultimately enhancing the properties of the steel. Common grades of calcium silicon wire include Si55 Ca28 and Si50 Ca28, with powder particle sizes ranging from 0-3mm or 1-3mm. The wire can also be customized to meet specific customer requirements.

|

Type |

chemical |

Diameter (mm) |

Sheath thickness (mm) |

Powder weight (g/m) |

Inner Dia. (mm) |

Outer Dia. (mm) |

coil height/ width (mm) |

|

|

CaSi Wire |

Si 50-60% Ca 28-30% |

13±0.8 |

0.4-0.45 |

220±10 |

600 |

1100 |

800-1200 |

|

|

Other specifications can be made according to customers requirement |

||||||||

Stable Alloy Composition

The use of calcium silicon cored wire allows for precise control over the amount of alloy added, minimizing material waste and improving overall metallurgical efficiency.

Excellent Deoxidation and Desulfurization

The strong reducing properties of silicon-calcium alloy make it highly effective in deoxidizing and desulfurizing steel, leading to improved steel quality and fewer defects in the final product.

Improved Steel Performance

Calcium Silicon Cored Wire helps to reduce inclusions, refine the grain size, and enhance the tensile strength and toughness of the steel, resulting in a stronger, more durable end product.

Ease of Use

Calcium silicon cored wire is easy to use, requiring no additional equipment or complex procedures. It can be applied in various steelmaking furnaces with minimal adjustments.

Cost-Effective Solution

By optimizing the steel production process, calcium silicon cored wire enhances yield and reduces operational costs, offering a cost-effective solution for steel manufacturers.

Environmental Benefits

By reducing sulfur content and other impurities, calcium silicon cored wire contributes to the production of cleaner, greener steel, with fewer emissions and environmental impact.

Calcium silicon wire is a steelmaking additive made by encasing silicon-calcium alloy powder in cold-rolled steel strip. It is fed into molten steel through the slag layer using a wire-feeding machine, achieving a calcium recovery rate of up to 24.32%. This product serves dual functions of deoxidation and desulfurization, effectively purifying inclusions in the molten steel and improving both the castability of the steel and the performance of the final product.

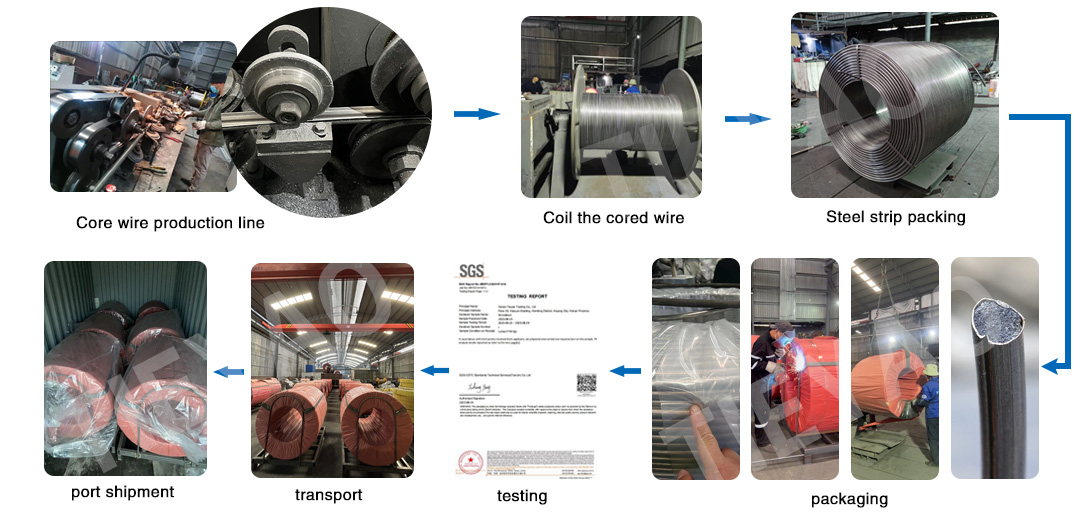

Alloy Powder Preparation:

The calcium silicon powder used contains a calcium content of ≥28% and a silicon content of 55-65%.

Powder Wrapping:

The calcium silicon powder is wrapped in a 0.4-0.45mm low-carbon steel strip, with the core material's filling density controlled within ±2%.

Forming and Sealing:

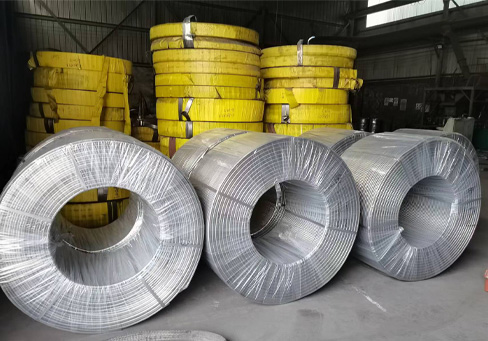

The edges are sealed using a cored wire rolling machine, and the wire is wound into coils weighing 1-2 tons, using a mold with an inner diameter of 600mm.

Packaging:

The coils are bundled with steel strips, wrapped in three layers of film, and then placed either horizontally or vertically on iron frames and pallets for shipping.

Calcium-silicon wire is widely used in the smelting of high-quality steel, low-carbon steel, stainless steel, and special alloy steels. It is particularly suitable for the following applications:

Steel mills: Used for desulfurization, deoxidation, and alloying treatments during the refining process in furnaces.

Electric arc furnace steelmaking: Improves the cleanliness of electric arc furnace steel.

Continuous casting process: Controls the composition of molten steel, resulting in more uniform properties of the cast steel.

Calcium-silicon wire is typically fed into molten steel using automatic wire feeding equipment. The feeding speed should be adjusted based on the molten steel's temperature, composition, and specific process requirements. Once introduced into the molten steel, the calcium-silicon alloy powder disperses rapidly, fully reacting with the steel to achieve the desired results.

Wire Feeding Method

During the refining process, a wire feeding machine is used to introduce the calcium-silicon wire into the molten steel at a controlled speed and depth, allowing adequate reaction time. This method ensures a higher calcium recovery rate and more effective calcium treatment, and it is the most widely used method by steel manufacturers.

Alternative Methods

In addition to the wire feeding method, there are other techniques for adding calcium-silicon alloy to molten steel, such as powder injection and projectile injection. However, the wire feeding method remains the preferred choice due to its simplicity, ease of operation, and higher calcium recovery rate.

1. What is Calcium Silicon Cored Wire used for?

Calcium Silicon Cored Wire is primarily used in steelmaking for deoxidation and desulfurization of molten steel, improving the quality of steel products.

2. How does Calcium Silicon Cored Wire improve steel quality?

It helps in removing oxygen and sulfur impurities from molten steel, preventing defects and enhancing the overall quality of the finished product.

3. What sizes do you offer for Calcium Silicon Cored Wire?

We offer Calcium Silicon Cored Wire in various diameters such as 13mm. Custom sizes can also be provided upon request.

4. What are the shipping options?

We offer global shipping with timely delivery. Our products are securely packed to prevent any damage during transit.

We manufacture various cored wires, such as Ferro Titanium Cored Wire, Calcium cored wire, Calcium ferro cored wire, Carbon cored wire, ReSiMg wire, etc.

Please feel free to submit your inquiry information to us, We will reply to you as soon as possible.